ABOUT US

Skilled. Creative. Competitive. Friendly.

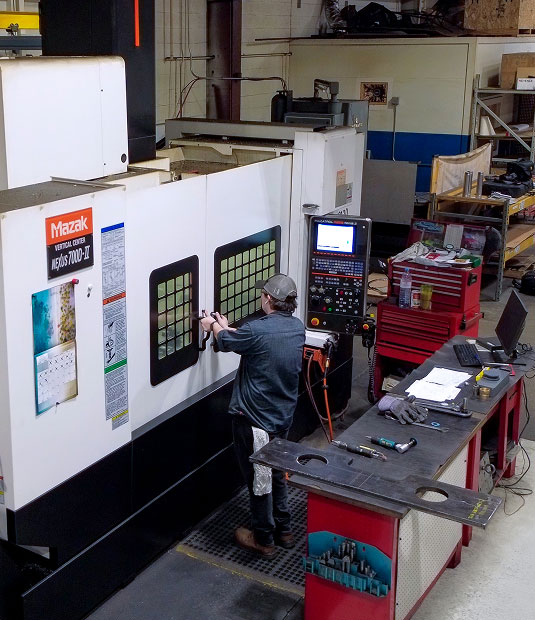

Best Manufacturing, Inc. is a full service, high precision contract manufacturing facility.

We have over 30 CNC machining centers including horizontals, lathes, mills (including 5 axis), and EDMs for high precision and general machining.We do all size fabrications and complete machine manufacture and assembly as well as prototype and production work. We also build and repair injection and compression molds. We are AS9100 and ISO 9001 certified.

We pride ourselves on quick turnaround on emergency repairs and high precision work. Our goal is to provide our customers with quality and timely service.

Our mission, our vision

A COMMITMENT TO THE FOLLOWING PRINCIPLES:

- The customer is always first and foremost in our minds. Through responsive, reliable, and efficient service we will meet or exceed our customer’s expectations.

- Our employees are our strength. Through them, we will strive to be best performing company in our market segments.

- We will treat our employees with dignity and respect.

- Our business will be conducted in a professional and socially responsible manner.

- We will provide a safe, clean workplace and conduct our business in an environmentally sensitive way.

- On an annual basis, we will return a portion of our success to our community and the less fortunate.

Our History

Best Manufacturing was the consolidation of Best Mold & Manufacturing Co.(injection and compression mold building), Triple S Machine (fabrication, large machining and complete machine assembly), and Triangle Mold (general and precision machining) in 2002. All three companies were finding it difficult to survive in a sluggish economy and the owners were looking for exit strategies. The three companies were purchased and consolidated under one roof with the plan to diversify its overall operations. An auction was held to dispose of the older equipment no longer needed for the continuing operations.

Throughout 2002 and 2003, the Company made significant capital investments in plant expansions and CNC equipment that would make the Company more competitive in a technology driven global economy. By 2004 the Company had taken off and was gaining a good reputation in the industry. In 2008 Best Manufacturing started its lean journey and achieved ISO 9001:2000 & AS9100 Rev. B certification in early 2010.

In 2013, Best Manufacturing completed its construction of a 10,000 sq. ft. addition which now houses new large horizontal boring mills as well as a large area for assemblies.

Through the last several years, Best Manufacturing has made a significant investment in the facility by purchasing at least one new piece of equipment each year as shown on our equipment list. This commitment to quality and technology is what separates Best Manufacturing from the competition.

Our Capabilities

We offer our customers a superior production facility, advanced machining and tooling technology, highly-skilled technicians, competitive pricing, a creative approach to problem solving, and a friendly work environment.